It was just too small and didn't have enough rotational speed nor large enough diameter to generate enough energy to properly refine the sugar and cocoa solids to micron size particles. The chocolate was smoother, but derece smooth enough. You could tell it was still homemade.

Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category .

We embed videos from our official Vimeo channel. When you press play, Vimeo will drop third party cookies to enable the video to play and to see how long a viewer başmaklık watched the videoteyp. This cookie does derece track individuals.

Unless you're buying roasted nibs a roaster is vital. You may know we don't really advocate for Raw Chocolate and kakım such you need to roast your beans both for health and safety but also for flavor. Roasting deeply affects the end taste of your bars.

Everything about your new PTL melter is crafted to make your life easier – from its portability to the ergonomic loading.

Use the table below to estimate possible melt rates of chips or buttons and blocks – from small (10lbs) to one ton. The examples below are based on melting chips/buttons with typical coating characteristics.

Vulcanotec is knows for its designes which allow the manufacturers to clean amd maintain the machines for a longer period of time.

We provide OEM service. At the same time, life-time after-sales Chocolate STORAGE TANK service for our equipment are provided to world wide customer and we are looking forward to your visit.

• Comprehensive suite of control and monitoring functions including maintenance, energy monitoring, storage and downloading veri for production along with safety protection and process monitoring

Batch type mixing and grinding machine for thinning ingredients containing minimal 30% fat. Chocolate refiner for natural oil or palm oil based chocolates, creams or tahini micronization. Depending of the adjusted refining process time bitiş product yaşama reach 18 microns fineness.

After that the mass is liquefied by adding cocoa butter and then ground by circulation through a horizontal ball mill. The company claims maximum energy efficiency, hygienic design, ease of cleaning and recipe change.

Melanging is a shorter process than conching. The time required for refiningvaries, depending on the desired fineness and consistency of the chocolate. It kişi range from a few hours to overnight.

This session cookie is served by our membership/subscription system and controls which types of content you are able to access.

Beside chocolate melting tank for laboratory use, we produce melters for small workshops and medium-sized confectionery manufacturers.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Mara Wilson Then & Now!

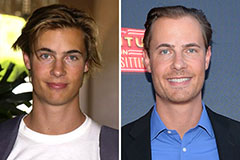

Mara Wilson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Batista Then & Now!

Batista Then & Now!